Promoting products from any angle

Sleeve Labels

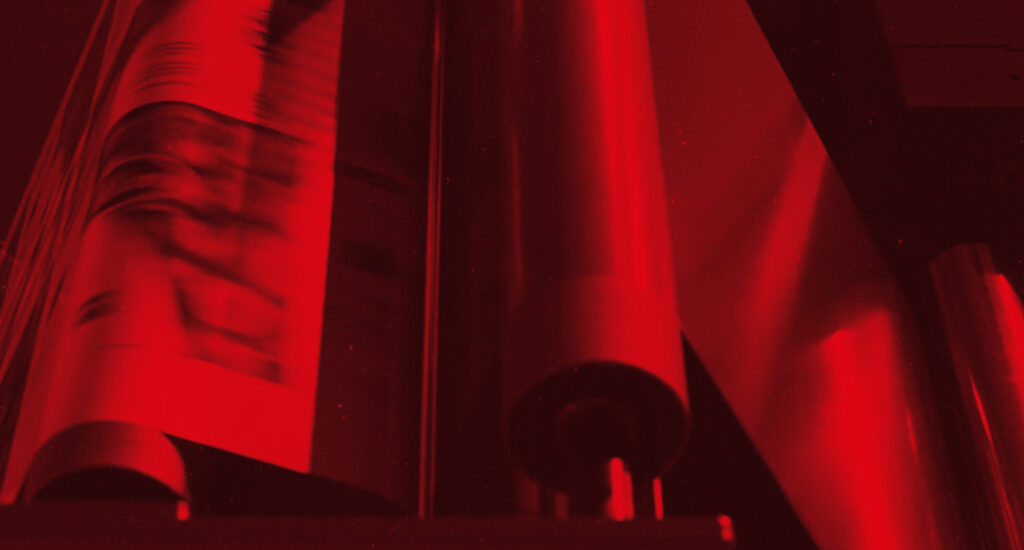

The sleeve label market offers vast possibilities in advanced product branding and packaging. Since the early 80s, rotary label presses have been developed, modified, and trimmed for handling various types of mono web sleeve materials.

Sleeves can be divided into three major types: Shrink sleeves, wrap-around sleeves, and stretch sleeves. Each individual sleeve type offers its own unique features and applications.

Offering full product decoration of bottles, containers, canisters, and more, shrink sleeves have successfully gained a footing over the latest 30 years. With the sleeve, you can decorate the product with 360° graphics, you may form the sleeve, so it fits very different and complex shapes, and you may even offer a tamper-evident solution to the overall packaging.

Wrap-around sleeves offer high-speed application for large product series. Overall, it is safe to say, that sleeve application is a valid alternative to traditional wet-glue or pressure sensitive labels. Today, the sleeve market makes up app. 15% of the global label market.

The primary sleeve materials are PVC, PET-G, PP, PLA, OPS, and PE for shrink, wrap-around, and stretch sleeves. Performance and price are the common denominators for these materials. The increase in oil prices is driving up the cost of polymers. Therefore, there is a large pressure on development of thin films, co-extruded films, and other films with innovative functions.

The Nilpeter presses are developed for multiple substrates. Our presses manage advanced tension controls, as well as web temperature management. These two challenges are the predominant factors to be mastered in order to achieve successful high-speed sleeve printing. Nilpeter delivers presses for sleeve printing based on offset and UV-flexo technology, water and solvent based flexo technology, gravure, as well as digital InkJet technology. Combined with various value-adding enhancements, our sleeve solutions are the broadest and most competitive in the market for high quality sleeves.

Over the years, Nilpeter has built-up an extensive know-how of sleeve production. We are committed to providing the optimum consultancy on sleeve technology to our customers. We work closely with our wide network of partners within the entire hard- and software supply chain.