Increasing shelf appeal

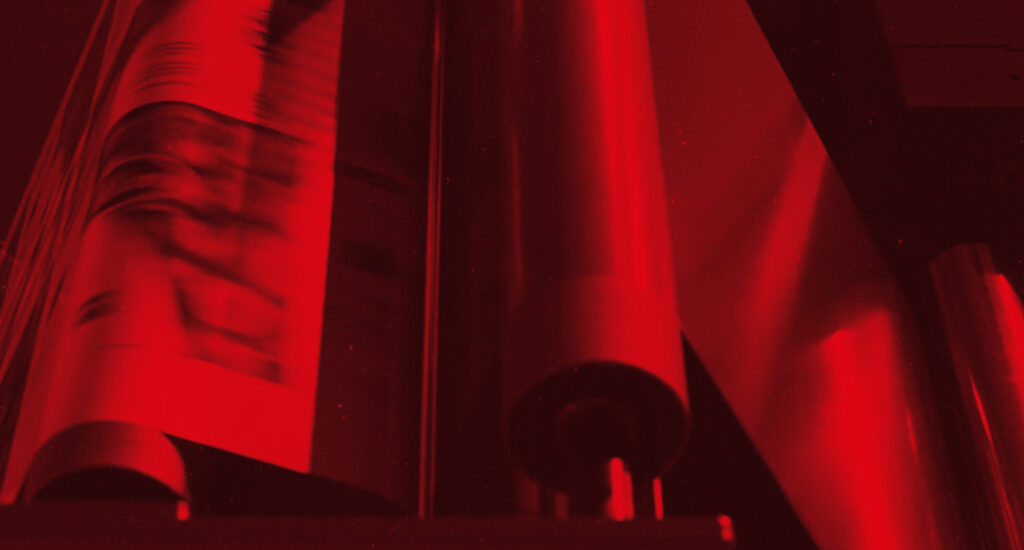

Tube Laminate Printing

Today many of our everyday products, from toothpaste, cosmetics, and personal care products to foods, are contained in squeezable tubes. The market is constantly growing, and many traditional forms of packaging, especially multi-national brands, are moving into tubes with its flexible benefits and decoration abilities.

A tube laminate consists of an innovative film laminate constructed of various composites with specific properties. One of these composites is typically a printable outer laminate, which is laminated with a barrier film. This film could be aluminium or other film types suitable as embedded aroma barrier.

Working with tube laminate, which is pre-printed material, has many advantages. It offers an option to make complex images utilising a full 360° printable image. A large quantity of printed laminate can be stored without any expensive storage of finished tubes. The immediate benefits of using tube as a packaging container are safe sealing, high quality printing of images, and use of highly effective barrier films depending on requirements.

Printing on tube laminate is challenging and puts high demands on the printing presses and technology. The materials from the various tube laminate suppliers often vary in their tolerances and flexible construction, hence the need for very accurate web tension controls, register controls, and other specially developed applications, such as additional web enhancement, print/varnish flow-out.

For a number of years, Nilpeter has supplied some of the leading tube laminate printers. Based on our close cooperation with these premier companies, of which we are very proud, we have refined our tube printing applications to perfection.